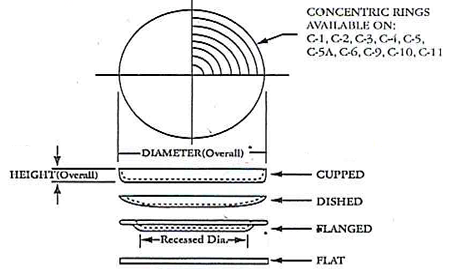

These planchets are ideal for evaporating samples and using in counters. We stock planchets in all sizes and shapes, aluminum, stainless steel and nickel. Please specify ringed or flat bottom (it is the same price).

| Type | Stock # | Diameter Overall | Height Overall | Recessed Diameter | List price per 1000 pieces | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| inches | mm | inches | mm | inches | mm | Aluminum | Stainless | nickel | ||

| Cupped | C-1 | 1 | 25.4 | 3/32 | 2.4 | 340.00 | 420.00 | |||

| C-2 | 1 | 25.4 | 1/4 | 6.4 | 340.00 | 420.00 | ||||

| C-3 | 1 | 25.4 | 5/16 | 7.9 | 340.00 | 420.00 | ||||

| C-4 | 1.25 | 31.8 | 3/32 | 2.4 | 340.00 | 420.00 | ||||

| order online | C-5 | 2 | 50.8 | 3/32 | 2.4 | 420.00 | 672.00 | |||

| order online | C-5A | 2 | 50.8 | 1/8 | 3.2 | 420.00 | 672.00 | |||

| C-6 | 2 | 50.8 | 5/32 | 4.0 | 420.00 | 672.00 | ||||

| C-7 | 1/16 | 52.4 | 3/32 | 2.4 | 420.00 | 672.00 | ||||

| C-8 | 1/16 | 52.4 | 5/32 | 4.0 | 420.00 | 672.00 | ||||

| C-9 | 2 | 50.8 | 3/16 | 4.8 | 420.00 | 672.00 | ||||

| order online | C-10 | 2 | 50.8 | 1/4 | 6.4 | 420.00 | 672.00 | |||

| C-11 | 2 | 50.8 | 5/16 | 7.9 | 420.00 | 672.00 | ||||

| C-12 | 60.0 | 1/8 | 3.2 | 420.00 | 672.00 | |||||

| C-12A | 3-3/8 | 80.0 | 5/32 | 5.5 | 1197.00 | 1950.00 | ||||

| C-12B | 60.0 | 6.4 | 490.00 | 810.00 | ||||||

| C-13A | 4-3/16 | 106.4 | 1/8 | 3.2 | 1614.00 | 2800.00 | ||||

| C-13 | 4-3/16 | 106.4 | 1/4 | 6.4 | 1467.00 | 2800.00 | ||||

| C-14 | 4-1/2 | 114.3 | 1/8 | 3.2 | 1614.00 | 2800.00 | ||||

| C-15 | 4-7/8 | 123.8 | 5/32 | 4.0 | 2500.00 | 4025.00 | ||||

| Dished | D-A | 1 | 25.4 | 3/32 | 2.4 | 320.00 | 420.00 | |||

| D-1 | 2 | 50.8 | 5/32 | 4.0 | 420.00 | 672.00 | ||||

| D-2 | 2-1/16 | 52.4 | 5/32 | 4.0 | 420.00 | 672.00 | ||||

| Flanged | FL-1 | 1-5/8 | 41.3 | 5/64 | 2.0 | 1-5/16 | 33.3 | 600.00 | 720.00 | |

| FL-2 | 1-5/8 | 41.3 | 1/8 | 3.2 | 1 | 25.4 | 600.00 | 720.00 | ||

| FL-3 | 2-5/16 | 58.9 | 5/32 | 4.0 | 2-3/32 | 53.2 | 495.00 | 810.00 | ||

| FL-4 | 2-5/16 | 58.9 | 5/16 | 7.9 | 2-3/32 | 53.2 | 495.00 | 810.00 | ||

| Flat | F-C | 5/8 | 15.9 | A:

367.00 C:451.00 D:502.00 |

A:451.00 C:561.00 D:624.00 |

1070.00 | ||||

| F-B | 11/16 | 17.5 | 1070.00 | |||||||

| F-A | 3/4 | 19.0 | 1070.00 | |||||||

| F-AA | 7/8 | 22.0 | 1070.00 | |||||||

| F-1 | 1 | 25.4 | 1070.00 | |||||||

| F-2 | 1-1/4 | 31.8 | ||||||||

| F-3 | 1-1/2 | 31.8 | 420.00 | 571.00 | ||||||

| F-3A | 1-3/4 | 44.0 | 420.00 | 672.00 | ||||||

| F-3B | 115/16 | 49.2 | 420.00 | 672.00 | ||||||

| F-4 | 2 | 50.8 | 420.00 | 672.00 | ||||||

A - Bulk

C - With Protective Tape

D - One per Envelope

A planchet is a round metal disk used to evaporate samples in a laboratory setting. An older word for planchet is flan. Planchets are also referred to as blanks. The preparation of the planchet has varied over the years. In ancient times, the planchet was heated before striking because the metal that the planchets were made out of was not as hard as dies today, and the dies would have worn faster and broken sooner had the planchet not been heated to a high temperature to soften it.

Today's planchets are made from hardened steel, and the presses use many thousands of pounds of force form the planchets. Because of this, the planchet no longer needs to be heated immediately before striking, although it is annealed by heating and quick cooling which softens the planchet.

Preparation of the modern planchet involves several steps. First, the metal (or metals in the case of clad or multilayered planchets) is rolled out into a large roll or sheet of the correct thickness. These flat rolls or sheets of metal are then punched out into round planchets that are a little larger than the planchet being struck. The planchets are then subjected to an annealing process that softens the metal through heating to approximately 750 degrees Celsius (1400 degrees Fahrenheit) and are then quickly quenched in water. They are then washed to remove residue from the annealing process and dried. The blanks then go through an upsetting mill that raises the rim on the edge of the planchet.